Most Popular Products

|

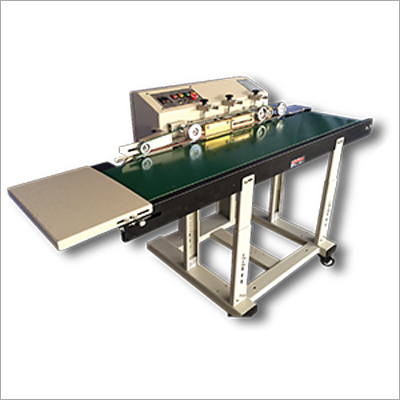

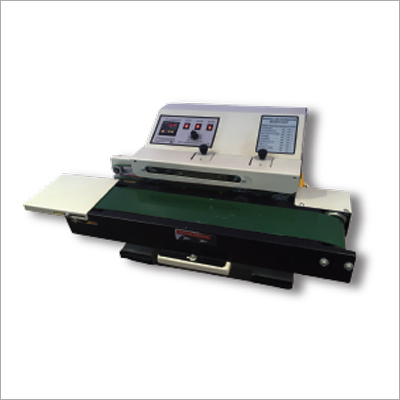

Deluxe Horizontal Band Sealers

MOQ : 1 Piece

Deluxe Horizontal Band Sealers Specification

- Sealing Speed

- 0 12 m/min (Adjustable)

- Automation Grade

- Semi-Automatic

- Voltage

- 220V / 50Hz Volt (v)

- Driven Type

- Electric

- Filling Capacity

- Up to 3 kg Kg

- Condition

- New

- Power

- 650 W Watt (w)

- Dimension (L*W*H)

- 840 x 380 x 320 mm Millimeter (mm)

- Application

- Pouch Sealing

- Color

- Gray/Green

- Packaging Speed

- Up to 300 bags/hour Pieces/Minute

- Weight

- 32 kg Kilograms (kg)

- Sealing Type

- Heat Sealing

- Seals Type

- Horizontal

- Packaging Material

- Plastic, Polyethylene, Polypropylene, Laminated Films

- Type

- Horizontal Band Sealer

- Sealing Length

- Continuous

Deluxe Horizontal Band Sealers Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- Piece

- Delivery Time

- Week

About Deluxe Horizontal Band Sealers

Specification

|

Country of Origin |

Made in India |

|

Orientation |

Horizontal |

|

Capacity |

3 to 12 Meters / Min |

|

Model Name/Number |

Horizontal Band Sealer |

|

Automation Grade |

Semi-Automatic |

|

Brand |

Pack O Matic |

- Teflon Belt : 25mm

- Motor System :Single (Italian Make)

- Machine Speed : 7 meters/min

- Conveyor Belt : 300mm x 1500mm

Robust Construction for Enhanced Longevity

Crafted from high-grade stainless steel, this horizontal band sealer offers exceptional durability and resistance to corrosion. Its solid structure supports rigorous use in industrial environments, ensuring smooth operation and minimal maintenance downtime. The robust design also contributes to consistent sealing quality.

Efficient Pouch Sealing with Adjustable Settings

This sealer handles a wide range of packaging materials including plastic, polyethylene, polypropylene, and laminated films. The adjustable sealing width, temperature controls, and conveyor options make it versatile for bags of varying sizes and thicknesses, accommodating diverse packaging needs in food, pharmaceuticals, and more.

Advanced Features for Quality Assurance

Offering both analog and digital controls, the sealer ensures precise settings for sealing speed, temperature, and print requirements. Its in-built embossing printer adds batch or product information directly to the seal, boosting traceability and compliance for manufacturers and exporters.

FAQs of Deluxe Horizontal Band Sealers:

Q: How does the Deluxe Horizontal Band Sealer operate for continuous sealing?

A: This band sealer uses a horizontal conveyor system, enabling continuous pouch sealing. The product pouches are placed on the conveyor, where the sealing jaws and heating elements create a robust seal as the bag moves through the machine. Sealing speed is adjustable up to 12 m/min.Q: What types of packaging materials are compatible with this sealer?

A: The machine is designed to seal a range of materials including plastic, polyethylene, polypropylene, and laminated films. The adjustable temperature and sealing width allow users to accommodate various bag thicknesses and film types efficiently.Q: When should the temperature range be adjusted during operation?

A: The temperature should be set based on the type and thickness of the packaging material. Thicker or multilayered films generally require higher temperatures (up to 300C), whereas thinner plastics can be sealed at lower settings. Adjustments can be made at any time using the control panel during operation.Q: Where is this horizontal band sealer commonly used?

A: This sealer is suitable for packaging operations in food processing units, pharmaceutical companies, and manufacturing sectors, especially among exporters and suppliers in India. Its high production capacity makes it ideal for medium to large-scale operations.Q: What is the process for using the in-built embossing printer feature?

A: After placing the pouch on the conveyor, users can configure the embossing printer from the control panel to print batch numbers, dates, or product codes directly onto the seal. This helps ensure traceability and compliance with packaging standards.Q: What benefits does the cooling system provide during sealing?

A: The air-cooled system rapidly cools the sealed area, ensuring strong and secure seals. This minimizes the risk of deformation or weak seals, enhancing overall package integrity, especially at high sealing speeds.Q: How does this sealer improve packaging accuracy and productivity?

A: With high automation and adjustable features, the sealer delivers consistent, precise seals and integrated printing for up to 300 bags per hour. This improves workflow efficiency, supports quality assurance, and meets the demands of high-volume production environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Deluxe Band Sealers Category

Deluxe Vertical Band Sealers

Minimum Order Quantity : 1 Piece

Weight : 32 kg Kilograms (kg)

Color : Green & White

Sealing Type : Continuous Heat Seal

Dimension (L*W*H) : 800 x 380 x 550 mm Millimeter (mm)

Contact Load : Standard

|

PACIFIC PLASTICS INDUSTRIES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry