Most Popular Products

|

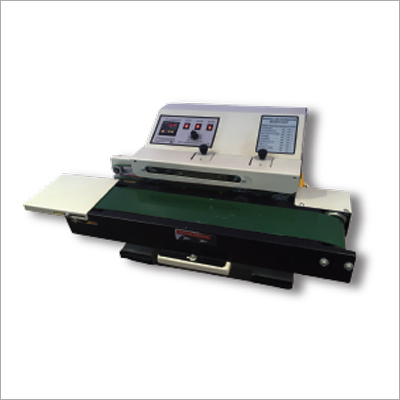

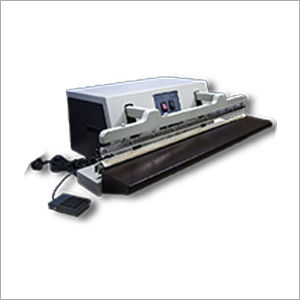

Vertical Big Band Sealer

MOQ : 1 Piece

Vertical Big Band Sealer Specification

- Voltage

- 220V/50Hz Volt (v)

- Condition

- New

- Type

- Vertical Big Band Sealer

- Sealing Type

- Heat Sealing

- Dimension (L*W*H)

- 1060 x 470 x 380 mm Millimeter (mm)

- Driven Type

- Electric

- Seals Type

- Continuous Band Seal

- Accuracy

- High sealing accuracy (1 mm) mm

- Automation Grade

- Semi-Automatic

- Power

- 600 W Watt (w)

- Application

- Sealing large pouches and bags, food, pharmaceuticals, chemicals, and grains

- Sealing Length

- No Limit (depends on bag length)

- Packaging Material

- Laminated films, PE, PP, Aluminum Foil

- Color

- Green/Metallic Grey

- Weight

- Approximately 30-40 kg Kilograms (kg)

- Sealing Speed

- 0-12 m/min

- Filling Capacity

- Up to 5 kg per bag Kg/hr

- Temperature Range

- 0°C - 300°C (Variable)

- Control Panel

- Digital temperature controller, speed regulator

- Frame Material

- Mild Steel (powder coated), Stainless Steel options

- Cooling System

- Integrated air cooling fans

- Conveyor Belt Width

- 200 mm

- Conveyor Height Adjustment

- Yes, adjustable conveyor platform

- Max Pouch Thickness

- Up to 0.08 mm

- Printing Device

- Optional batch coding/embossing

Vertical Big Band Sealer Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 7 Pieces Per Week

- Delivery Time

- 2-3 Week

About Vertical Big Band Sealer

Vertical Big Band Sealer is a highly advanced packaging unit that is widely used in the packaging line of various industries to make sealed packages. It is fabricated by using heavy engineering materials that make it capable to bear heavy impacts forces and high temperatures. It is installed with an easy-to-use programmable control system to easily set operational parameters. Vertical Big Band Sealer is high in demand due to its high durability and efficiency.

Versatile Sealing Solution

Crafted for sealing large pouches and bags across multiple sectors, the Vertical Big Band Sealer supports a range of packaging materials like laminated films, PE, PP, and aluminum foil. With no sealing length limitation and height-adjustable conveyor, this machine adapts to various pouch sizes and thicknesses for seamless productivity.

Precision and Efficiency

The digital temperature controller ensures precise heat settings, while the integrated air cooling fans enhance sealing strength for perfectly sealed packages every time. With high sealing accuracy (1 mm) and the ability to handle up to 720 bags per hour, this sealer is ideal for medium-to-high volume production environments.

Robust Build and User-Friendly Controls

Constructed with a powder-coated mild steel frame and available in stainless steel, the unit is designed for longevity in demanding industrial settings. Its digital control panel, speed regulator, and optional batch coding device make the sealer both intuitive and adaptable for a variety of production needs.

FAQs of Vertical Big Band Sealer:

Q: How does the adjustable conveyor height benefit the sealing process?

A: The adjustable conveyor platform allows you to align the sealer precisely to the size of your pouches or bags, reducing spillage and ensuring consistent, secure seals regardless of product size.Q: What types of materials and bag sizes can this sealer handle?

A: This Vertical Big Band Sealer is compatible with laminated films, PE, PP, and aluminum foil packaging, and can accommodate bags up to 5 kg each with any length, as sealing length depends on the bag.Q: When should I adjust the temperature range on the machine?

A: You should set the appropriate temperature (between 0C and 300C) according to the type and thickness of packaging material to achieve optimal sealing results without damaging the material.Q: Where can this sealer be effectively used?

A: Ideal for food processing, pharmaceuticals, chemicals, and grains sectors, this machine is widely utilized in factories, packaging centers, and exporter facilities throughout India and abroad.Q: What is the process for using the sealer with batch coding?

A: To utilize the batch coding or embossing function, simply activate the optional printing device on the control panel. The sealer will automatically imprint batch numbers or other details onto each bag during the sealing process.Q: How does the integrated air cooling system improve sealing quality?

A: The built-in air cooling fans quickly set the seal after heating, preventing overheating and ensuring every bag achieves a strong, professional finish with minimal wastage or errors.Q: What benefits do the digital control panel and speed regulator offer?

A: The digital panel and speed regulator provide easy monitoring and precise adjustments to sealing temperature and conveyor speed, enabling you to tailor operations for maximum efficiency and consistent, high-quality seals on every bag.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

PACIFIC PLASTICS INDUSTRIES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry